News

Manufacturing Point-of-Care Diagnostic Kits—Speed, Precision, and Scalability

Manufacturing Point-of-Care Diagnostic Kits—Speed, Precision, and Scalability The demand for point-of-care (POC) diagnostic kits is at an all-time high. These compact, easy-to-use test kits are revolutionizing how healthcare is delivered—bringing...

Sterile Liquid Filling & Packaging—Precision That Powers Diagnostics and Care

Sterile Liquid Filling & Packaging—Precision That Powers Diagnostics and Care n diagnostic, medical, and life science applications, even the smallest inconsistency in liquid fills can compromise test results, regulatory approval,...

Reagent Kit Manufacturing—Scalable, Sterile, and Regulatory-Ready

Reagent Kit Manufacturing—Scalable, Sterile, and Regulatory-Ready As the need for precise, rapid diagnostic tools grows across clinical, research, and biotech sectors, reagent kits are becoming indispensable. Whether they're used for...

Diagnostic Device Manufacturing—A Full-Service Approach from Prototype to Production

Diagnostic Device Manufacturing—A Full-Service Approach from Prototype to Production The global demand for diagnostic devices has surged, driven by advances in point-of-care testing, home health solutions, and precision medicine. From...

Cleanroom Kitting & Private Label Packaging for Life Science Products

Cleanroom Kitting & Private Label Packaging for Life Science Products Packaging is more than just protection—it’s an extension of your brand, your product’s compliance trail, and your end-user’s first experience....

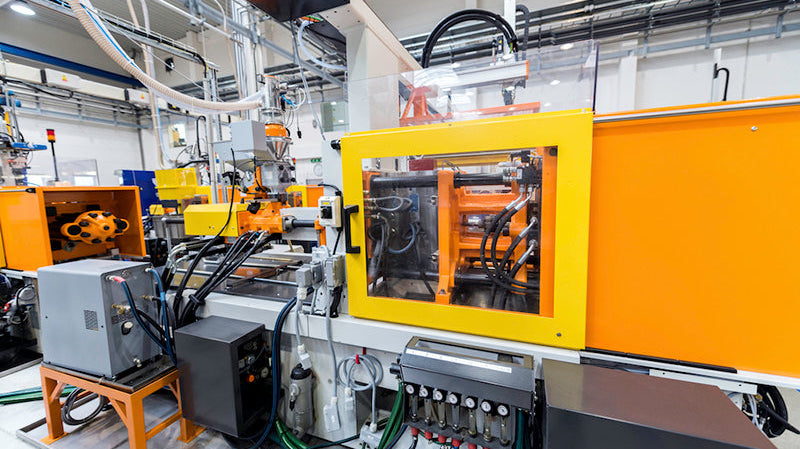

Benefits of In-House Tooling for Rapid Prototyping and Production

Benefits of In-House Tooling for Rapid Prototyping and Production In today’s competitive product development landscape, speed and precision make all the difference. Whether you're an early-stage startup or an established...

Cleanroom Kitting & Private Label Packaging for Life Science Products

Cleanroom Kitting & Private Label Packaging for Life Science Products Packaging is more than just protection—it’s an extension of your brand and a critical step in regulatory compliance. At Ciro...

Why ISO 13485 Certification Matters in Medical Manufacturing

Why ISO 13485 Certification Matters in Medical Manufacturing In medical manufacturing, quality isn’t a differentiator—it’s a requirement. Products that come into contact with patients, body fluids, or critical diagnostic samples...

From Mold to Market—A Deep Dive into the Integrated Manufacturing Process

From Mold to Market—A Deep Dive into the Integrated Manufacturing Process In today’s fast-paced product development environment, speed, precision, and risk reduction are non-negotiable—especially in industries like medical devices, diagnostics,...

Onshore vs. Offshore Manufacturing—Why U.S.-Based Production Gives You the Advantage

Onshore vs. Offshore Manufacturing—Why U.S.-Based Production Gives You the Advantage In today’s globalized economy, manufacturing partners can be found across every continent. Yet, for companies in the medical, biotech, and...

From Mold to Market—Why Integrated Manufacturing Reduces Risk

From Mold to Market—Why Integrated Manufacturing Reduces Risk When launching or scaling a product in the life science, medical device, or biotech sectors, complexity is often the biggest hurdle. Multiple...

The Benefits of ISO-Class Cleanroom Assembly in Medical Manufacturing

The Benefits of ISO-Class Cleanroom Assembly in Medical Manufacturing In the medical and life science industries, precision isn't optional—it's mission-critical. At Ciro Manufacturing, we operate in an ISO Class 6...