Life Science Contract Manufacturing—From Prototyping to Full-Scale Production

The life sciences industry is evolving rapidly—driven by innovations in diagnostics, biotechnology, and personalized medicine. Startups and established brands alike are racing to bring safe, effective products to market while navigating strict compliance requirements and shifting global demand. That’s where life science contract manufacturing becomes critical.

At Ciro Manufacturing, we deliver vertically integrated contract manufacturing services tailored to life science companies. From initial prototype to ISO 13485-compliant mass production, we provide the infrastructure, expertise, and speed needed to scale new ideas into market-ready solutions.

What Is Life Science Contract Manufacturing?

Contract manufacturing in life sciences involves outsourcing production of components, kits, devices, or assemblies used in research, diagnostics, or healthcare delivery. Typical products include:

-

Diagnostic kits and test cartridges

-

Liquid reagent buffers and sample prep kits

-

Lab consumables and disposables

-

Collection tubes, swabs, and transport containers

Manufacturers must meet industry-specific quality standards, including FDA and ISO 13485 compliance, while delivering fast, flexible, and high-volume production.

Why Ciro Is a Strategic Partner for Life Science Brands

1. ISO 13485-Certified Quality Systems

Our entire manufacturing operation adheres to ISO 13485 standards, ensuring:

-

Full traceability of materials and components

-

Risk-based process controls

-

Documented SOPs, DHRs, and validation records

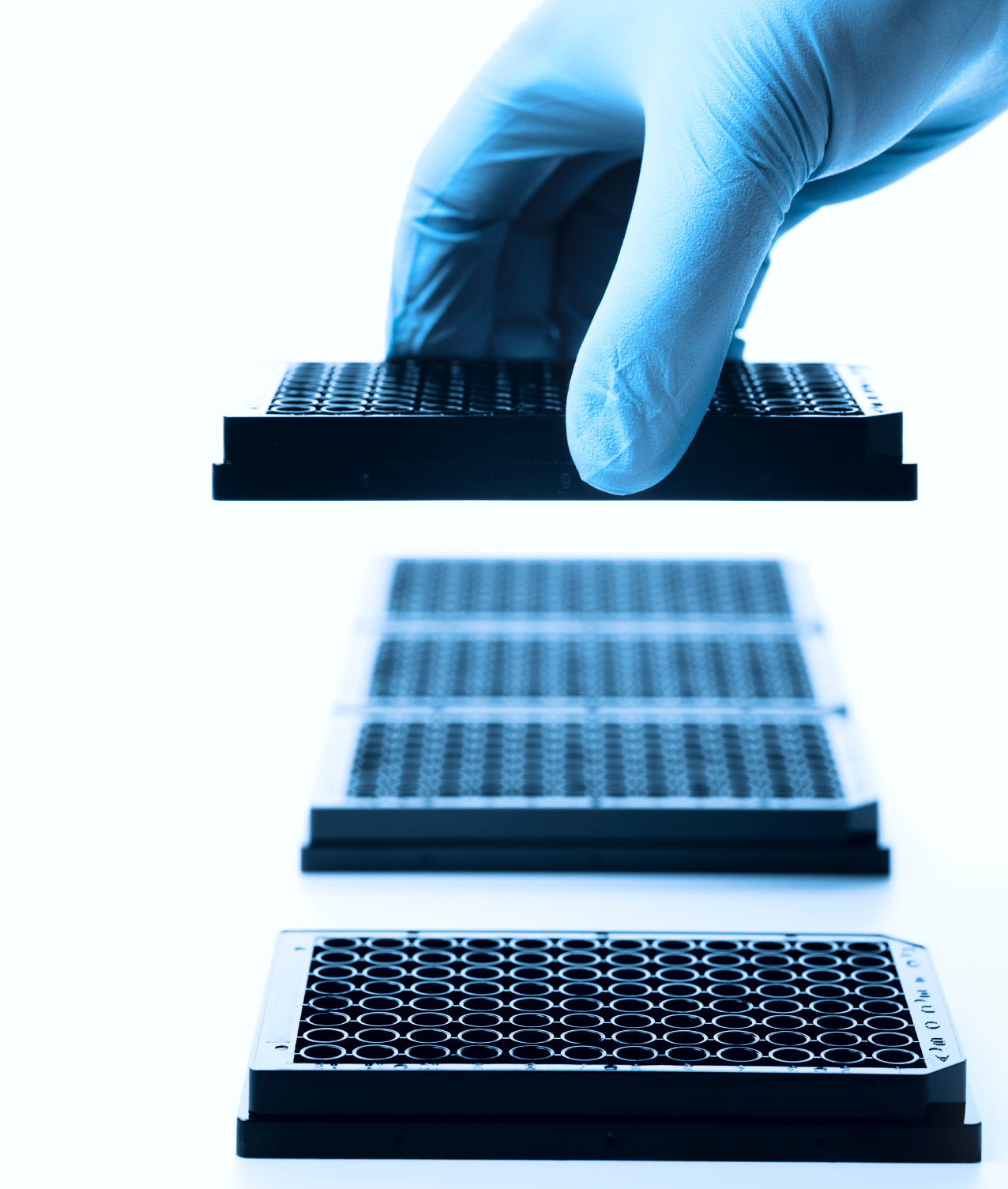

2. Cleanroom Assembly and Kitting

We offer cleanroom-controlled services ideal for sensitive biological and diagnostic products:

-

ISO Class 6 assembly

-

Custom reagent kit building

-

Lot-coded packaging with audit-ready documentation

3. Sterile Liquid Filling and Buffer Preparation

From PCR buffers to VTM solutions, we provide:

-

Fill volumes from 0.5 mL to 100+ mL

-

Batch-controlled liquid filling

-

Tamper-evident sealing and private labeling

4. Plastic Molding and In-House Tooling

Our injection molding services produce custom housings, caps, and diagnostic components with full design-for-manufacturability (DFM) support.

5. Flexible Scaling and Pilot Programs

We support life science brands at every stage, from pilot production to multi-million unit scale-ups. Our team collaborates on:

-

Product validation and verification

-

Tech transfer and clinical trial support

-

Forecast-driven inventory programs

Applications We Support in Life Sciences

-

Molecular and serological diagnostics

-

Biotech reagents and sample prep kits

-

Environmental and food safety testing

-

Public health surveillance kits

-

OEM private-label products for distribution

Case Study: Supporting a Clinical Trial Reagent Kit Rollout

A biotech firm developing a nucleic acid test needed to deploy 50,000 reagent kits for a Phase III trial. Ciro provided:

-

Custom tube filling with sterile buffer

-

Cleanroom kitting with barcode labeling

-

Lot-level documentation for FDA submission

The company was able to meet IRB timelines and collect clinical data on schedule.

Final Thought: Scale With a Partner Who Understands the Science

Ciro Manufacturing is more than a vendor—we’re a regulatory-savvy production partner built for the pace and precision of the life sciences industry. Whether you’re developing the next breakthrough diagnostic or scaling up a proven product, our integrated services keep your program moving forward.

👉 Let’s discuss your life science manufacturing needs.