Plastic Injection Molding Services—Precision Manufacturing for Regulated Industries

Plastic injection molding remains one of the most efficient and scalable ways to manufacture high-quality components for medical, biotech, and diagnostic products. At Ciro Manufacturing, our plastic injection molding services are built around precision, repeatability, and compliance—with every tool, material, and process engineered to meet the demands of regulated industries.

Whether you're launching a new diagnostic cartridge or scaling a medical device, our in-house team delivers the control, speed, and traceability you need to succeed.

What Is Plastic Injection Molding?

Injection molding is a manufacturing process that involves injecting molten plastic into a precisely machined mold cavity. Once cooled and solidified, the plastic forms a finished part with high dimensional accuracy and repeatability. It is ideal for producing:

-

Complex geometries

-

Thin-walled parts

-

Large volumes of identical components

-

Cleanroom-compatible medical parts

Our Injection Molding Capabilities

1. In-House Tool Design and Fabrication

We create molds in-house, offering:

-

Design for Manufacturability (DFM) consulting

-

Prototype and production tooling

-

Mold validation and maintenance

-

Rapid turnaround and modification services

2. Material Expertise for Medical and Life Science Applications

We process a broad range of thermoplastics including:

-

Polypropylene (PP)

-

Polycarbonate (PC)

-

ABS

-

COC/COP

-

TPEs and elastomers

All materials are selected for biocompatibility, sterilizability, and FDA/USP compliance.

3. ISO 13485-Certified Processes

Our injection molding operations follow documented SOPs and quality controls, including:

-

IQ/OQ/PQ validation

-

Batch documentation and lot traceability

-

Part inspection, sampling, and DHR generation

4. Scalability and Flexibility

We mold parts in:

-

Low, mid, and high volumes

-

Single and multi-cavity molds

-

Bridge, prototype, and commercial production settings

Why Choose Ciro for Plastic Injection Molding?

-

Vertical Integration: Molding, tooling, cleanroom assembly, and packaging all in one facility

-

Regulatory Alignment: ISO 13485-certified QMS ensures FDA, CE, and IVDR readiness

-

Shorter Timelines: Fast mold iterations and in-house production reduce delays

-

Cost Control: Efficient tooling and automation minimize per-part costs

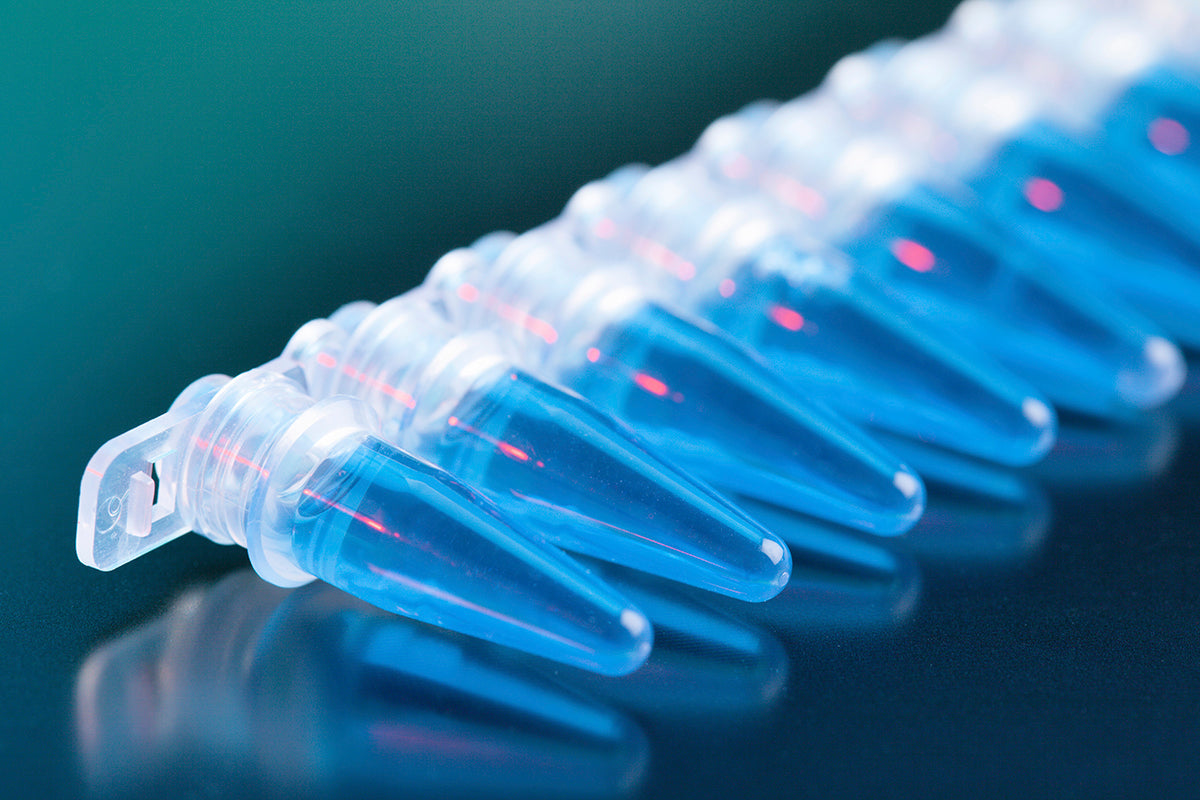

Ideal Applications

-

Diagnostic housings and test cassettes

-

Reagent reservoirs and vials

-

Swab handles and caps

-

Biotech sample processing components

-

Disposable labware and collection tubes

Case Study: Launching a Custom PCR Cartridge

A client developing a PCR-based diagnostic test needed a precision-molded cartridge housing. Ciro:

-

Designed and machined a custom multi-cavity mold

-

Molded PC components with <±0.002” tolerances

-

Delivered over 500,000 parts in 90 days with full traceability

Outcome: The client submitted for EUA and launched within regulatory deadlines.

Final Thought: Precision You Can Build On

At Ciro Manufacturing, our plastic injection molding services go beyond just shaping parts—we shape reliability, compliance, and scalability. When performance and quality matter most, our experience and in-house capabilities keep your production on track.

👉 Reach out to start your custom molding project today.